0 repins 0 comments 0 likes

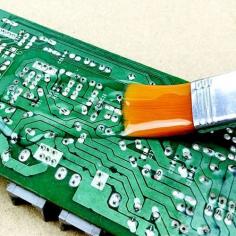

FS Technology is a company dedicated to pcb manufacturing and pcb assembly, located in Shenzhen, China. Here, we will introduce some information about our company and our view on the circuit board industry. If you are interested in us, welcome to our website.